Daya Bay comprises two identical (1026MW) Pressurised Water Reactor units with good safety track records. These units were French designed and manufactured with a 40 years lifespan. Given prudent operation and maintenance, the lifespan may be extended up to around 60 to 80 years.

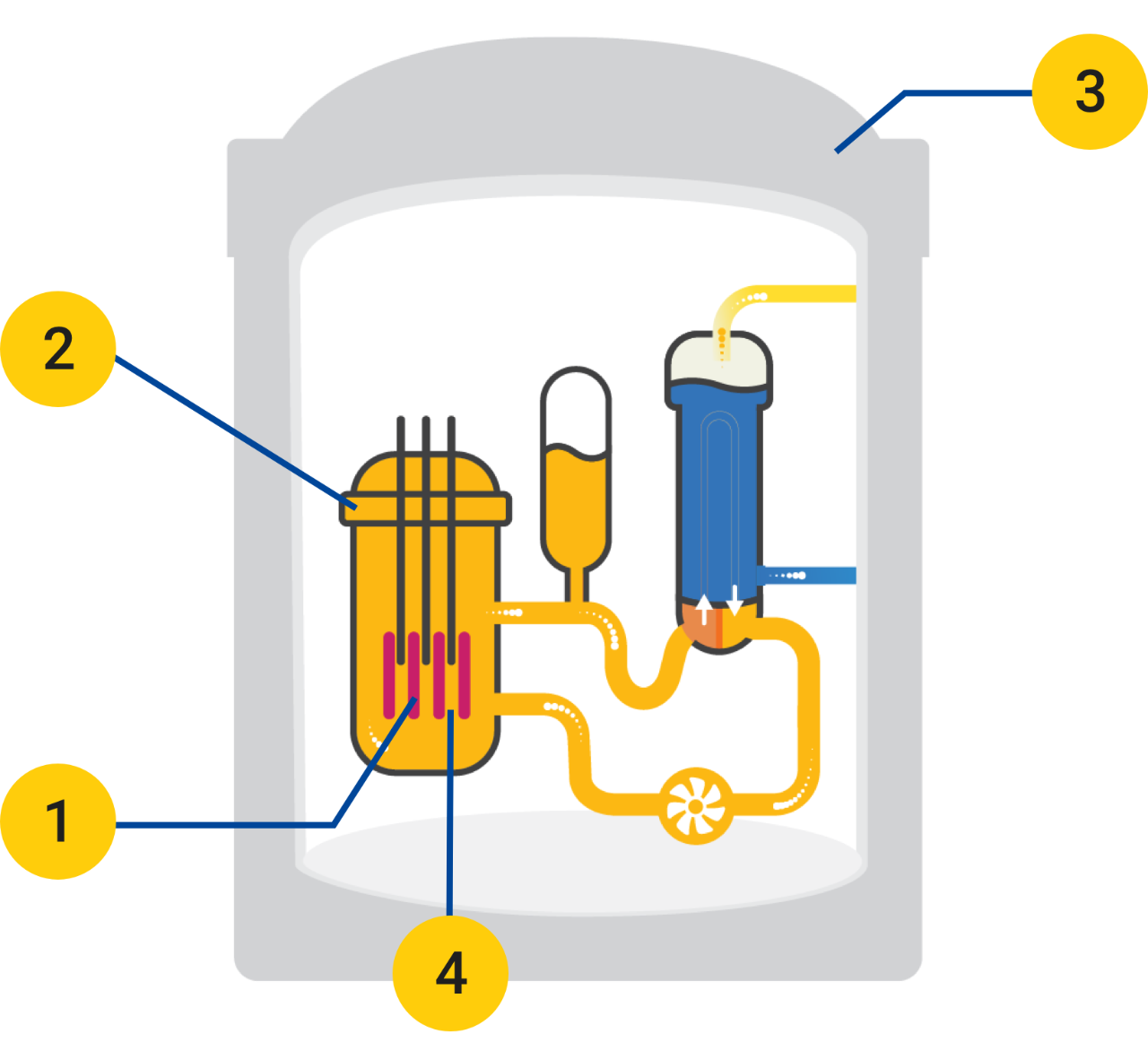

The nuclear island consists of a containment building and a fuel building. In which, the fuel building contains a fuel storage pool to store spare and spent nuclear fuel assemblies. Besides, the containment building contains the following systems for producing heat by nuclear reaction.

Nuclear Reactor–3 leak-tight barriers

The cladding encloses the radioactive material produced during nuclear fission and prevents it from escaping.

Its 200mm-thick steel wall keeps cooling water containing a minute amount of radioactive material within the primary coolant circuit.

A 900mm-thick pre-stressed concrete structure with a 6mm-thick steel interior lining houses the reactor pressure vessel. The containment building can withstand the impact of a large commercial aircraft.

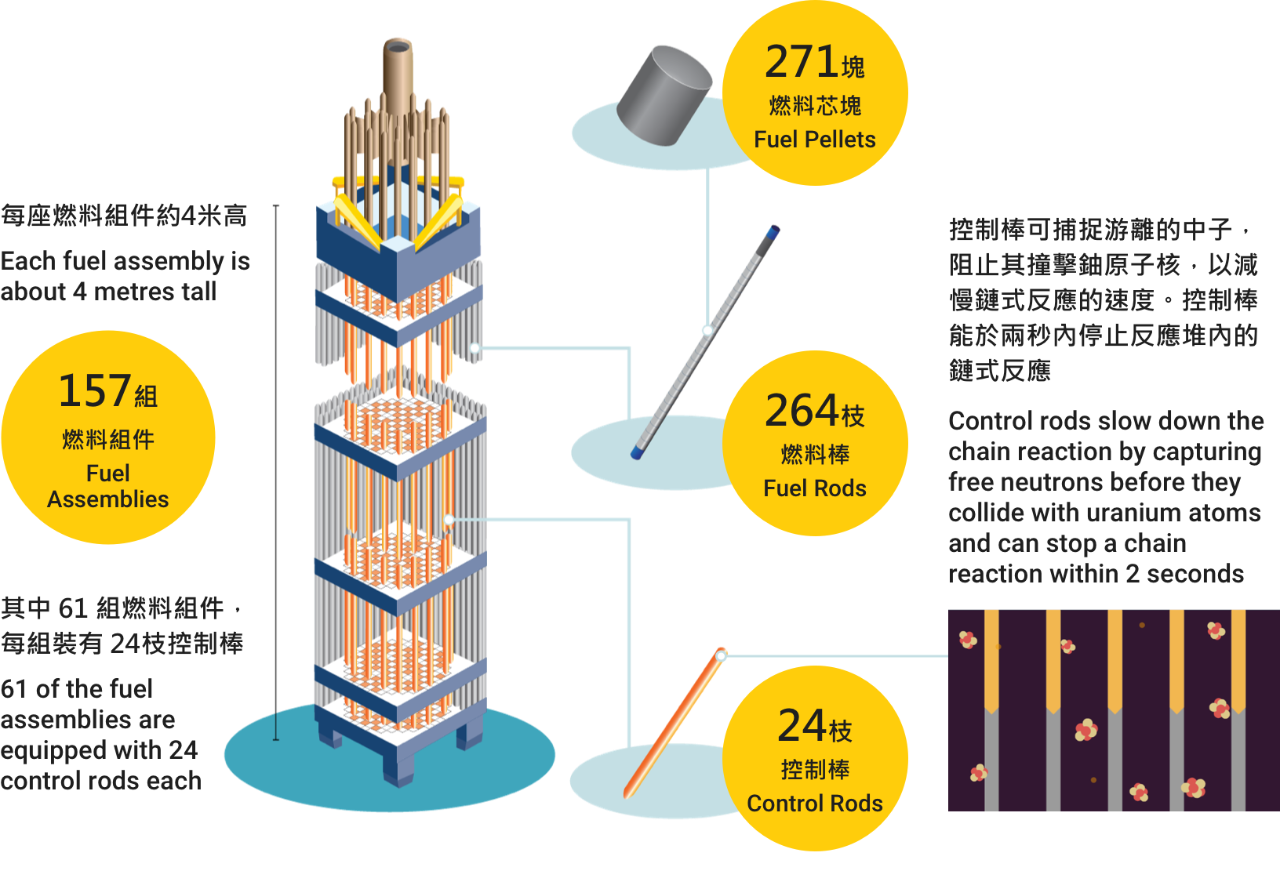

4. Nuclear Reactor Fuel Assembly

Each reactor includes 157 groups of 4-metre tall fuel assemblies, 61 groups of which each have 24 control rods. Each fuel assembly comprises 264 fuel rods and each fuel rod contains 271 fuel pellets. Each reactor core is therefore made up of 41,448 fuel rods and has a mass of about 80 tonnes.

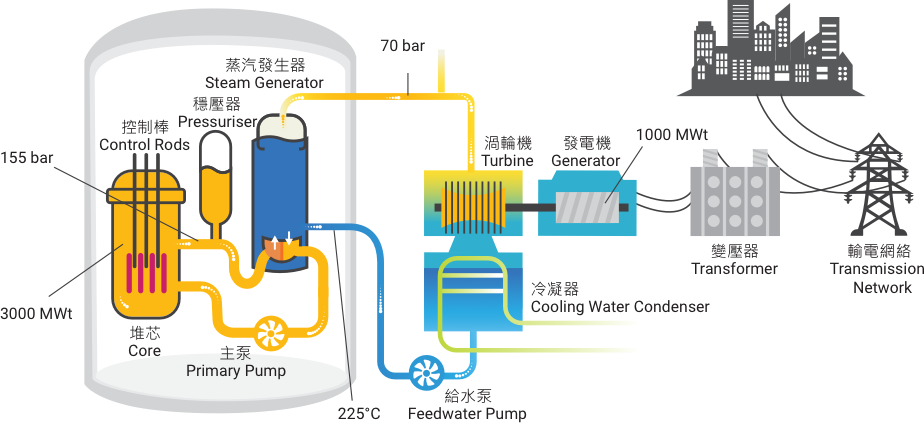

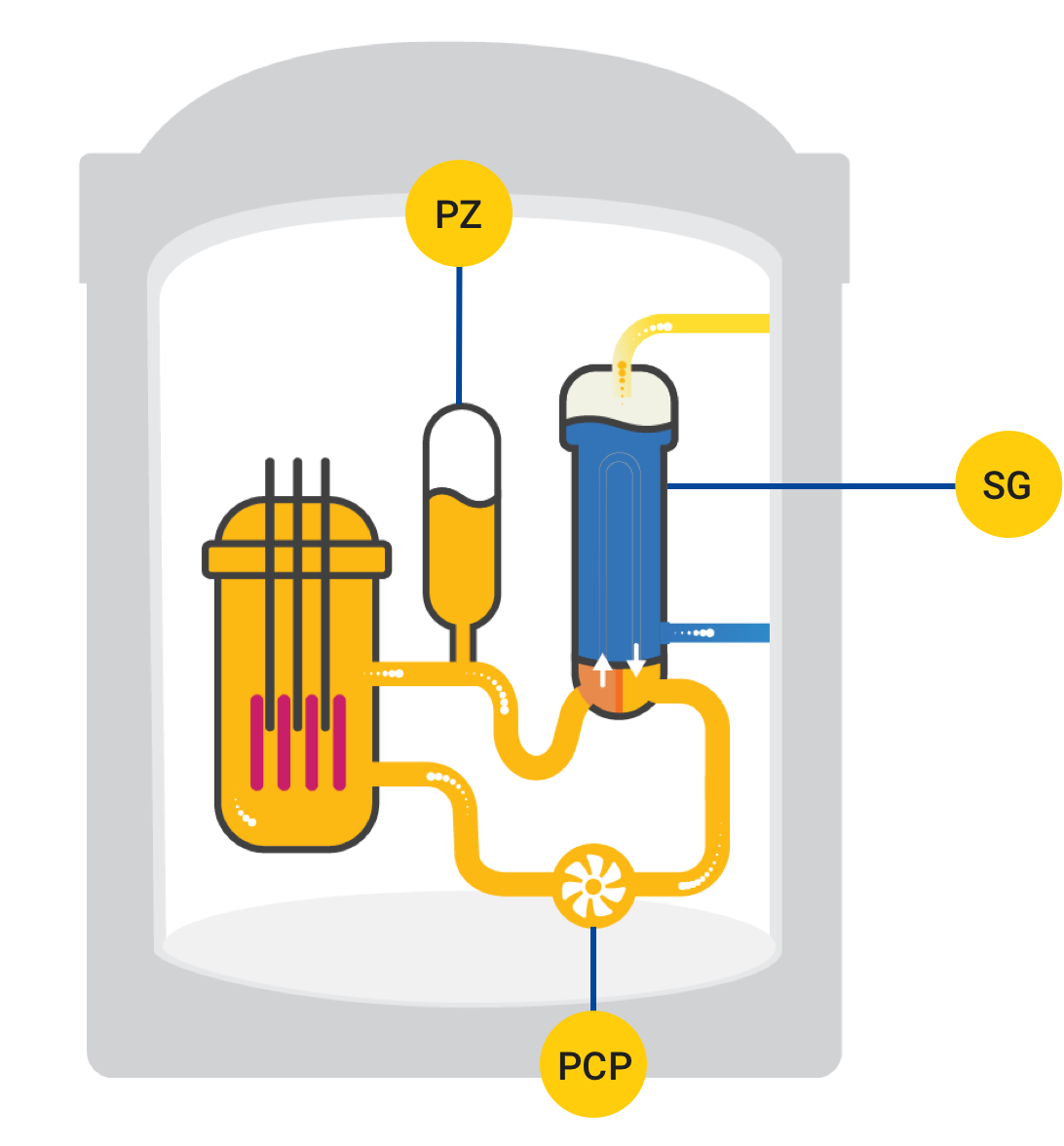

In the Pressurised Water Reactor design, the sealed water circuit cooling the nuclear reactor is called “primary-circuit”. The water flow is driven by 3 primary coolant pumps. A pump motor set is about 8 metres tall and uses about 6.5 MW of power, driving water at 6 tonnes per second.

The hot primary circuit is pressurised at 155 bar by the pressuriser to inhibit any steam bubble. The pressuriser is about 13 metres tall and weighs 80 tonnes.

In a steam generator, the hot primary circuit water flows up from the bottom inside U-tube bundle and boils up the cooler "secondary circuit" water outside the top of U-tube bundle to generate steam. Each steam generator contains over 4,400 number of 21 metres tall nickel-chromium alloy U-tubes and has an empty weight of about 330 tonne. It produces about half a tonne of steam per second.

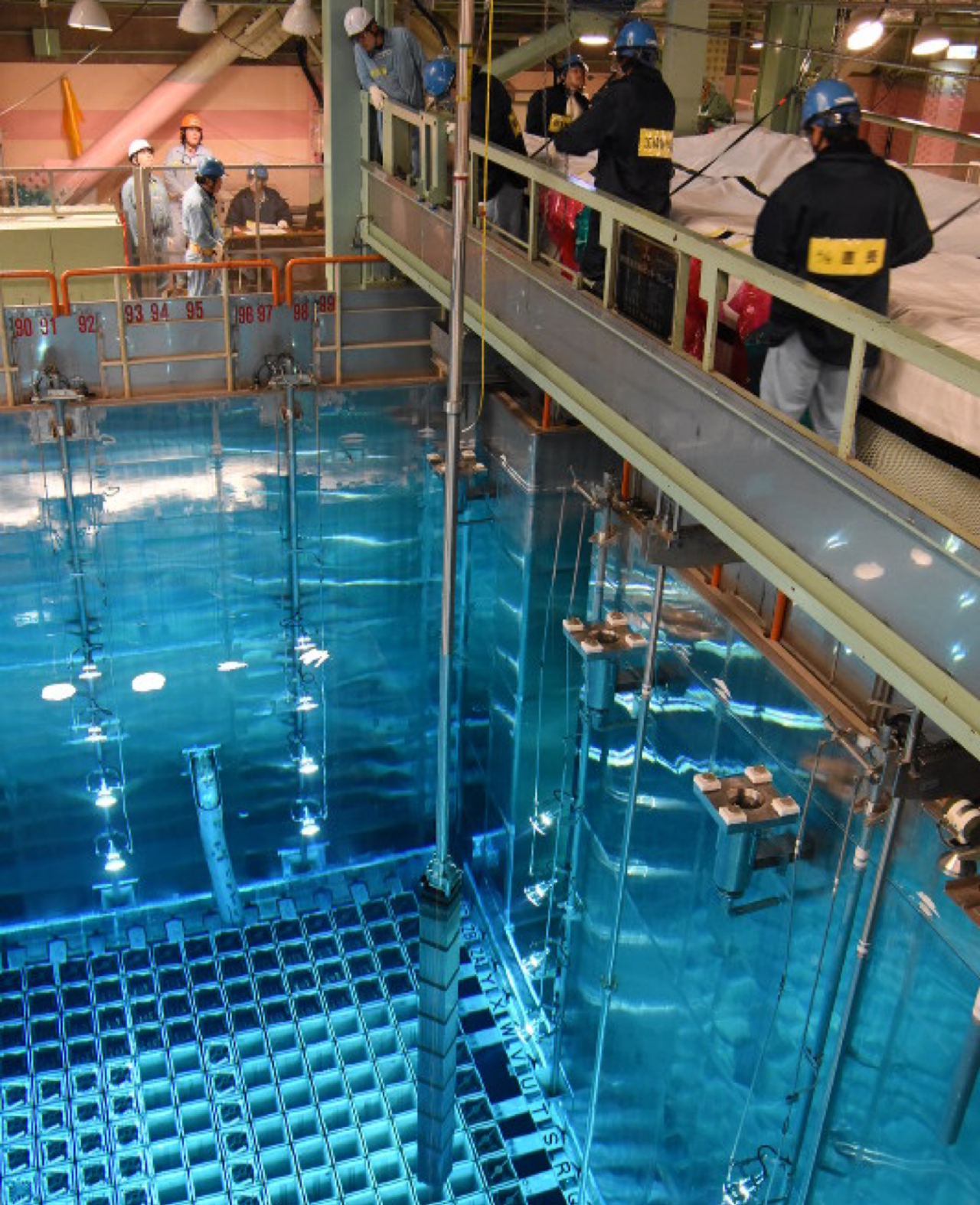

The Fuel Storage Pool

The fuel storage pool is used to store new, temporarily unloaded and spent nuclear fuel assemblies under water. The spent fuel assemblies can be delivered for the backend management of the nuclear fuel after 8 years of storage. The pool capacity is about a half of an Olympic size swimming pool though it is much deeper.

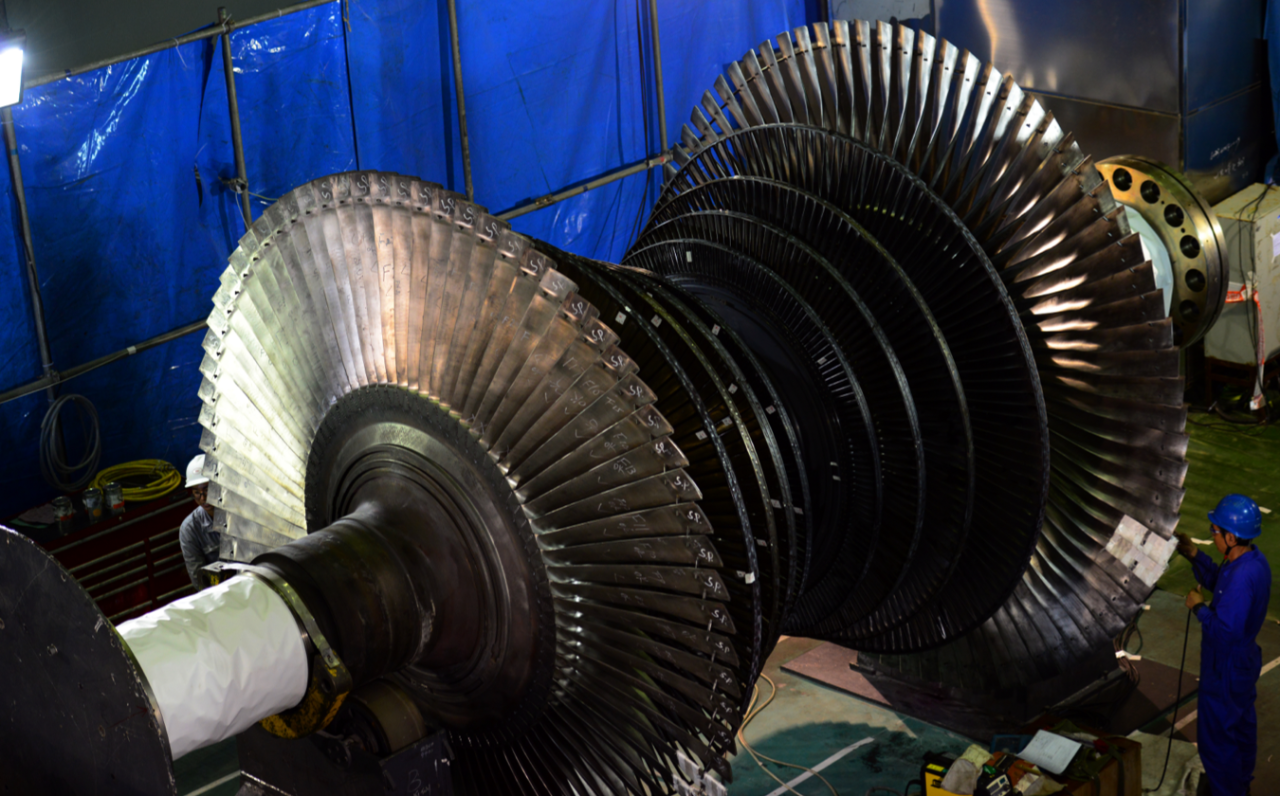

The conventional island contains the following main equipment to generate electricity through the steam taken across from the nuclear island.

The Turbine-Generator

The Moisture Separator-Reheater

Feed Pumps

At Daya Bay, the steam cooling is provided by physically separated seawater at 45 tonnes per second.

Read More About Daya Bay